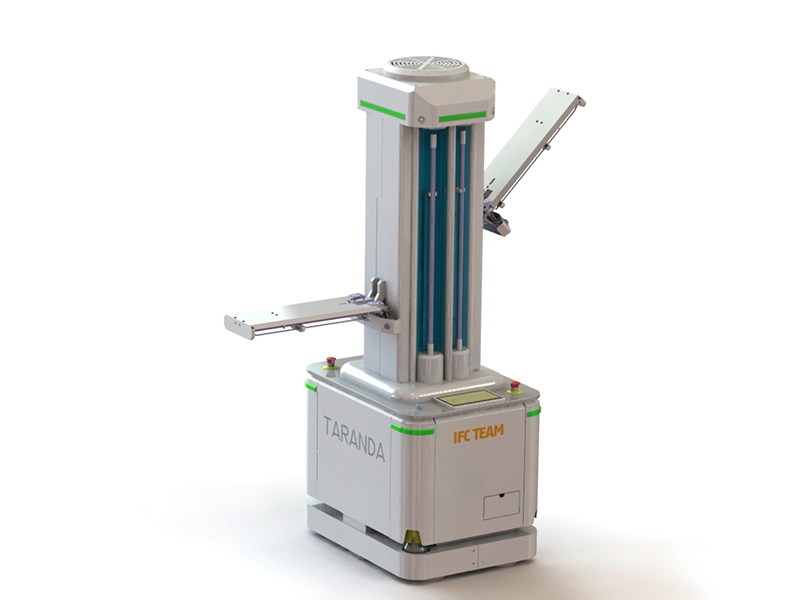

Insert loading station and automatic unloading of injection machine

In this application carried out in the injection division of a manufacturer in the automotive sector, the automatic loading of the eight inserts to be placed in the mold has been solved through an automatic collection system, once a vibrator has oriented and positioned them correctly.

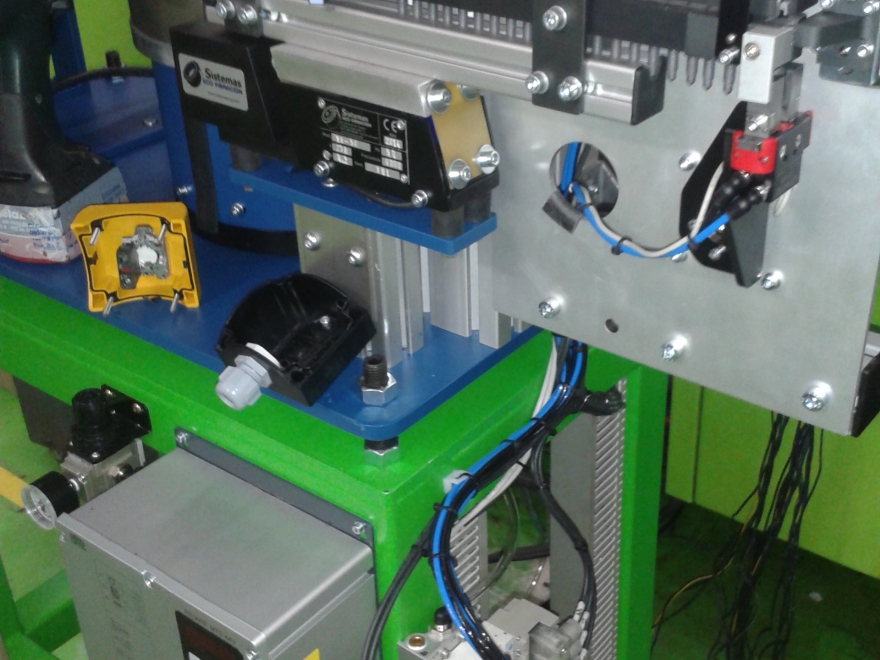

The insert collection system consists mainly of a series of independent pneumatic clamps, which guarantee their holding during transits and loading them into the double cavity mold.

Before placing the inserts in the mold, our solution includes a control area that guarantees that the positioning of the inserts in the robot's hand has been carried out correctly. The main objective of this process control is to avoid the injection of defective parts.