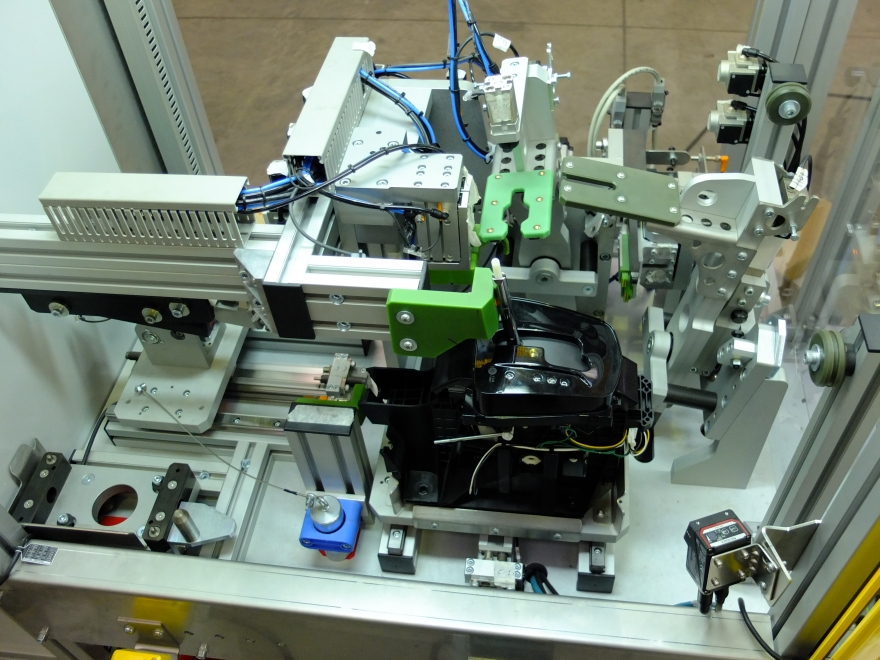

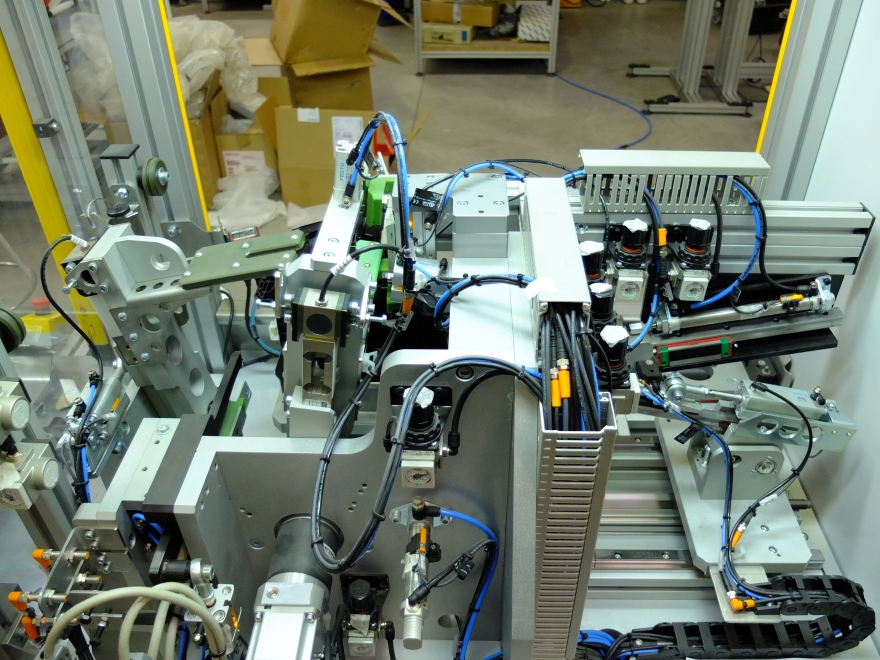

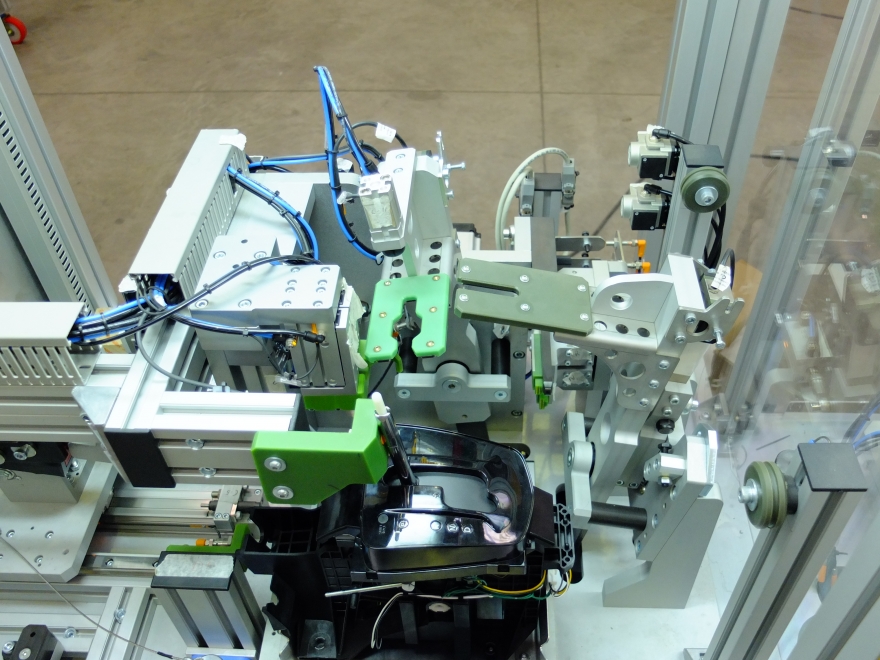

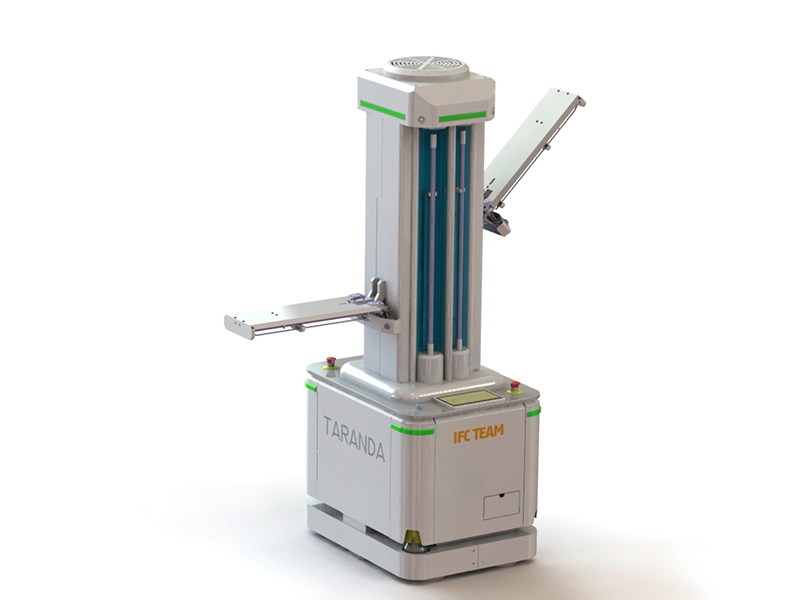

Automatic gear lever assembly and control line

IFC TEAM has recently delivered an automatic gear lever assembly line, where the actual assembly stations of the different components that make up the product overlap, with the EOLT (End Of Line Test) control at the end of the line, where they validate all the specifications to be met by the final deliverable set, from the connectivity of its terminals, the control of the efforts of the mobile elements, the ability to carry out all those movements for which the design is made, presence of critical components, etc.

Finally, if all these tests are positive, the label that validates the performance of all these tests is issued, certifying the quality of the product and releasing its shipment to the end customer.

Our client and IFC TEAM have been designing and building similar lines for many years, where electronics and control have been gaining ground in increasingly complex lines, where versatility and the ability to power in a few minutes with the massive use of SMEDs we can manufacture different products.

Likewise, our experience in assembly lines, and a very detailed analysis of the FMEA of the process allows us to develop POKA YOKES so that the error in the manufacturing process no longer occurs, filtering these immediately, preventing continuing in the process if there is any deviation in the same.